BMW > 6 Series (F12/F13) > C) CHASSIS, BRAKES, SUSPENSION & STEERING UPGRADES > - Wheel Spacers, Hub Extenders, Extended Wheel Bolts, Stud Conversion Kits Etc > ROGUE ENGINEERING

.jpeg)

Click to Enlarge

.jpeg)

Click to Enlarge

.jpeg)

Click to Enlarge

Click to Enlarge

Click to Enlarge

Click to Enlarge

Click to Enlarge

Click to Enlarge

Description

PLEASE NOTE: THIS PAGE OFFERS FULL PRODUCT DETAILS, TO ACTUALLY ORDER YOUR CHOSEN SPACER SET PLEASE GO TO THE VARIATIONS SECTION (USING THE RED BUTTON NEAR THE TOP RIGHT)

Wheel Spacers

A wheel spacer is a wheel spacer, right? WRONG! At Rogue Engineering, what started as a product to support the Big Brake Kits has turned into a unique product in itself. What many may consider a simple task, Rogue continue to improve the product to make wheel fitting requirements a little easier for the end user.

Construction and Material

Rogue Engineering wheel spacers start from 100% billet 6061-T6 aluminum round (not cut from plate). From there, they are machined entirely on CNC lathes and mills to ensure absolute roundness and thickness. Production runs are tested at random to ensure absolute balance, trueness and dimension.

Unique Features

Being longtime wheel spacer users, R been frustrated with common spacer issues. By addressing some of these minor issues, Rogue have been able to make a more functional wheel spacer.

One issue is the dreaded "stuck" spacer. There is the occasion, that a spacer may become "stuck" to the brake disc centre surface, making removal very difficult or near impossible. Because all wheel spacers that are produced have virtually flat back surfaces, you cannot wedge anything to pry off the spacer. Not even the thinnest screwdriver or chisel will fit. Rogue Engineering spacers now incorporate a newly designed "step" on the back side of the spacer, allowing for adequate tools to aid in the removal of the wheel spacer, in the event of a stubborn spacer.

Another issue, when dealing with spacers of multiple sizes, is being able to identify them easily without taking out a caliper to measure them. To make things easier, the thickness of the spacer is now thoughtfully engraved on the front side of the face.

The new "window" design removes safest amount of weight possible from the spacer itself. For example, the new 10mm spacer design is 25% lighter than another US marketed brand and 40% than a common German brand. With so much focus on lightweight wheels, installing a wheel spacer in excess of 1 pound seems like a neglected oversight. Now, with the new design, you can have your spacer while adding minimal weight to the wheel assembly area.

Sizing and Compatibility

Rogue Engineering manufactures a few popular, most requested sizes. All of the wheel spacers have a hubcentric lip which helps with the installation of wheels with the spacer in place. For this reason, Rogue do not produce sizes smaller than 10mm. By making spacers to this design, Rogue can produce unique sizes such as 12mm, originally designed for E46 M3s using Brembo big brake kits and OEM 18" wheels.

Rogue Engineering produce the following sizes:

- 10mm

- 12mm

- 15mm

- 18mm

PLEASE GO TO THE VARIATIONS SECTION (USING THE RED BUTTON NEAR THE TOP RIGHT)

All spacers fit BMW 5x120 bolt patterns with 72.5mm hub flanges (not E39, E70). Rogue do not produce any 4x100 patterns (older 3-series BMWs).

Rogue Engineering have also found issues with E90 325 Xi models as they have very high hub contour height. Customers must pre-measure the height to make sure it is less than 11.5mm tall, otherwise, they have to shave/grind down the hub face.

Wheel Bolt Information

All Rogue Engineering wheel spacers now include BLACK wheel bolts that are ISO/TS 16949 and ISO 9001 by TÜV. The finish is very close to BMW's OEM finish which is both corrosion resistant and durable.

Regardless of color of the bolts, wheel bolts should be considered consumable items. That's right, they do not last forever. If you never remove your wheels, this is a different story. However, if you remove and change wheels often (winter tires, track wheels, etc.), consider changing your hardware at least on a yearly basis to prevent premature hardware failure.

What Length Wheel Bolts?

Some aftermarket wheels may have THICKER than OEM wheel pad widths (for strength, added rigidity, or simply because of the design), and require longer than stock wheel bolts for adequate thread engagement. Because of the multitude of aftermarket wheels, we cannot provide technical data as to how long your bolts need to be to fit non-OEM wheels. Additionally, the bolts we provide with the spacers are designed to replace factory bolts on factory wheels. We do not offer mixing-matching of bolts with spacers to accommodate non-OEM wheel pad dimensions.

How Tight is Right?

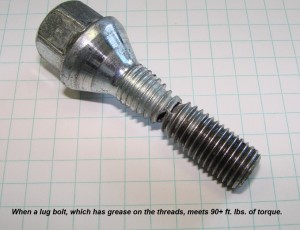

It is important to note lug bolt torque. Alongside, find picture a lug bolt torqued to 90 ft. lbs. (according to the customer) using grease on the threads. BMWs current specification on M12 wheel bolts is 88 ft. lbs. (higher for M14 bolts). This specification is with dry threads. Anti-seize, grease, or other lubricants on the threads of the bolt can, and will, artificially lubricate the threads, causing an inaccurate torque reading when using a torque wrench. This can yield a situation where the bolt is actually over-torqued (as shown in the case below).

IMPORTANT NOTES: A MUST READ! PURCHASING SPACERS FROM ROGUE ENGINEERING IMPLIES THAT YOU HAVE READ AND AGREE TO THE FOLLOWING!

Wheel bolts used with spacers installed and removed frequently should be considered consumables (like brake pads and brake discs) and should be replaced on a regular basis, based on use. Wheel bolts supplied means that you accept liability for measuring and ensuring that there are enough threads engaged for your wheel application, as all wheels can vary. Repeated installation and removal can cause wheel bolts to stretch and ultimately break. Torque on bolts should be checked on a regular basis. Replacement wheel bolts are available for purchase. We recommend checking bolt torque after the first 50-100 miles initially and regular intervals afterwards. Failure to do so may cause the wheel bolts to loosen and/or fail. Follow factory recommended wheel bolt torque.

Spacers are priced per pair (2), and include appropriately length wheel bolts (10).

Plese state which model when ordering.

Spacers are priced with wheel bolts included.

The hub surface upon which the wheel spacer will be mounted should be adequately prepared before installation. This means all surface corrosion should be cleaned with a wire brush or steel wool to ensure a clean surface. A thin film of grease or anti-seize compound on the face of the wheel hub will aid in the future removal of the spacer. The spacer should slide over the hub without being forced. Using a hammer, mallet or other "tools of persuasion" on the wheel spacer for installation is not recommended and immediately voids any product warranty.

Estimated Volumetric Shipping Weight : 2.00 Kg

Wheel Spacers

A wheel spacer is a wheel spacer, right? WRONG! At Rogue Engineering, what started as a product to support the Big Brake Kits has turned into a unique product in itself. What many may consider a simple task, Rogue continue to improve the product to make wheel fitting requirements a little easier for the end user.

Construction and Material

Rogue Engineering wheel spacers start from 100% billet 6061-T6 aluminum round (not cut from plate). From there, they are machined entirely on CNC lathes and mills to ensure absolute roundness and thickness. Production runs are tested at random to ensure absolute balance, trueness and dimension.

Unique Features

Being longtime wheel spacer users, R been frustrated with common spacer issues. By addressing some of these minor issues, Rogue have been able to make a more functional wheel spacer.

One issue is the dreaded "stuck" spacer. There is the occasion, that a spacer may become "stuck" to the brake disc centre surface, making removal very difficult or near impossible. Because all wheel spacers that are produced have virtually flat back surfaces, you cannot wedge anything to pry off the spacer. Not even the thinnest screwdriver or chisel will fit. Rogue Engineering spacers now incorporate a newly designed "step" on the back side of the spacer, allowing for adequate tools to aid in the removal of the wheel spacer, in the event of a stubborn spacer.

Another issue, when dealing with spacers of multiple sizes, is being able to identify them easily without taking out a caliper to measure them. To make things easier, the thickness of the spacer is now thoughtfully engraved on the front side of the face.

The new "window" design removes safest amount of weight possible from the spacer itself. For example, the new 10mm spacer design is 25% lighter than another US marketed brand and 40% than a common German brand. With so much focus on lightweight wheels, installing a wheel spacer in excess of 1 pound seems like a neglected oversight. Now, with the new design, you can have your spacer while adding minimal weight to the wheel assembly area.

Sizing and Compatibility

Rogue Engineering manufactures a few popular, most requested sizes. All of the wheel spacers have a hubcentric lip which helps with the installation of wheels with the spacer in place. For this reason, Rogue do not produce sizes smaller than 10mm. By making spacers to this design, Rogue can produce unique sizes such as 12mm, originally designed for E46 M3s using Brembo big brake kits and OEM 18" wheels.

Rogue Engineering produce the following sizes:

- 10mm

- 12mm

- 15mm

- 18mm

PLEASE GO TO THE VARIATIONS SECTION (USING THE RED BUTTON NEAR THE TOP RIGHT)

All spacers fit BMW 5x120 bolt patterns with 72.5mm hub flanges (not E39, E70). Rogue do not produce any 4x100 patterns (older 3-series BMWs).

Rogue Engineering have also found issues with E90 325 Xi models as they have very high hub contour height. Customers must pre-measure the height to make sure it is less than 11.5mm tall, otherwise, they have to shave/grind down the hub face.

Wheel Bolt Information

All Rogue Engineering wheel spacers now include BLACK wheel bolts that are ISO/TS 16949 and ISO 9001 by TÜV. The finish is very close to BMW's OEM finish which is both corrosion resistant and durable.

Regardless of color of the bolts, wheel bolts should be considered consumable items. That's right, they do not last forever. If you never remove your wheels, this is a different story. However, if you remove and change wheels often (winter tires, track wheels, etc.), consider changing your hardware at least on a yearly basis to prevent premature hardware failure.

What Length Wheel Bolts?

Some aftermarket wheels may have THICKER than OEM wheel pad widths (for strength, added rigidity, or simply because of the design), and require longer than stock wheel bolts for adequate thread engagement. Because of the multitude of aftermarket wheels, we cannot provide technical data as to how long your bolts need to be to fit non-OEM wheels. Additionally, the bolts we provide with the spacers are designed to replace factory bolts on factory wheels. We do not offer mixing-matching of bolts with spacers to accommodate non-OEM wheel pad dimensions.

How Tight is Right?

It is important to note lug bolt torque. Alongside, find picture a lug bolt torqued to 90 ft. lbs. (according to the customer) using grease on the threads. BMWs current specification on M12 wheel bolts is 88 ft. lbs. (higher for M14 bolts). This specification is with dry threads. Anti-seize, grease, or other lubricants on the threads of the bolt can, and will, artificially lubricate the threads, causing an inaccurate torque reading when using a torque wrench. This can yield a situation where the bolt is actually over-torqued (as shown in the case below).

IMPORTANT NOTES: A MUST READ! PURCHASING SPACERS FROM ROGUE ENGINEERING IMPLIES THAT YOU HAVE READ AND AGREE TO THE FOLLOWING!

Wheel bolts used with spacers installed and removed frequently should be considered consumables (like brake pads and brake discs) and should be replaced on a regular basis, based on use. Wheel bolts supplied means that you accept liability for measuring and ensuring that there are enough threads engaged for your wheel application, as all wheels can vary. Repeated installation and removal can cause wheel bolts to stretch and ultimately break. Torque on bolts should be checked on a regular basis. Replacement wheel bolts are available for purchase. We recommend checking bolt torque after the first 50-100 miles initially and regular intervals afterwards. Failure to do so may cause the wheel bolts to loosen and/or fail. Follow factory recommended wheel bolt torque.

Spacers are priced per pair (2), and include appropriately length wheel bolts (10).

Plese state which model when ordering.

Spacers are priced with wheel bolts included.

The hub surface upon which the wheel spacer will be mounted should be adequately prepared before installation. This means all surface corrosion should be cleaned with a wire brush or steel wool to ensure a clean surface. A thin film of grease or anti-seize compound on the face of the wheel hub will aid in the future removal of the spacer. The spacer should slide over the hub without being forced. Using a hammer, mallet or other "tools of persuasion" on the wheel spacer for installation is not recommended and immediately voids any product warranty.

Estimated Volumetric Shipping Weight : 2.00 Kg

Additional Information

Rogue Eng Wheel Spacer Oct 14